Repairing Cast Iron Radiators: What You Need to Know

Repairing cast iron radiators involves fixing cracks, sealing leaks, and restoring functionality. Methods include epoxy repairs, section replacement, and professional refurbishment for long-term results.

Cast iron radiators can develop cracks or leaks between sections, often due to age or stress. For small cracks, epoxy repairs work well. Clean the area thoroughly, apply a high-temperature epoxy, and let it cure completely. This is a temporary fix but can extend the radiator’s life.

Leaks between sections are common and usually caused by failed gaskets. You may need to disassemble the radiator, replace the gaskets, and reseal the joints. This requires draining the system, so ensure you have the right tools and patience. If unsure, consult a professional to avoid further damage.

For restoration or refurbishment, stripping old paint and rust is essential. Use a wire brush or sandblasting to clean the surface. Apply a rust inhibitor and repaint with heat-resistant paint. This not only improves appearance but also prevents future corrosion.

Older radiators may need section replacement if damage is severe. Salvage parts from unused radiators or order new ones. Aligning sections properly ensures even heat distribution and prevents leaks.

Regular checks help catch issues early. Look for rust, leaks, or uneven heating. Addressing problems quickly saves money and keeps your radiator efficient. If the job feels too complex, hiring a specialist ensures safe and effective repairs.

How to Identify Common Cast Iron Radiator Problems

Cast iron radiators develop issues over time, and recognizing them early prevents major damage. Visible cracks often appear near joints or along the body. These may start as hairline fractures but can widen under pressure. Rust spots indicate corrosion, especially in areas with paint damage. Persistent leaks between sections suggest worn gaskets or loose connections.

Uneven heating points to sludge buildup inside the radiator. Cold spots at the bottom mean blockages restrict hot water flow. Knocking or clanking noises often result from trapped air or loose internal components. Peeling paint exposes the metal, accelerating rust.

Check for water pooling beneath the radiator, signaling active leaks. Discoloration or stains on walls or floors near the unit often accompany hidden leaks. If sections feel loose or misaligned, the internal seals may have degraded.

Temporary Fixes for a Cracked Cast Iron Radiator

Small cracks can be managed temporarily until a permanent solution is possible. Epoxy putty works well for sealing minor fractures. Clean the area with a wire brush, apply the epoxy, and smooth it before it hardens. High-temperature sealants also work for hairline cracks but may not last long under constant heat.

For leaks at threaded connections, pipe tape or thread sealant can reduce dripping. Tightening loose bolts might stop minor leaks, but avoid over-torquing to prevent further damage. Radiator stop-leak additives poured into the system can seal small internal cracks, though they are not a long-term fix.

These solutions buy time but should not replace proper repairs. Monitor the radiator closely, as temporary fixes can fail unexpectedly.

Step-by-Step Guide to Fixing Leaks Between Sections

Leaks between sections usually mean gaskets or seals have failed. Before starting, gather these tools: adjustable wrenches, replacement gaskets, sealant, a bucket, and rags.

1. Turn off the heating system and drain the radiator. Locate the drain valve, attach a hose, and empty the water into a bucket.

2. Loosen the nuts connecting the leaking sections. Use two wrenches—one to hold the radiator steady, the other to turn the nuts counterclockwise.

3. Separate the sections carefully. Remove the old gasket and clean the mating surfaces with a wire brush.

4. Apply high-temperature sealant to the new gasket. Position it between the sections and realign them.

5. Tighten the nuts evenly. Alternate between them to ensure uniform pressure and prevent warping.

6. Refill the system and check for leaks. Pressurize slowly and inspect the repaired area.

When to Disassemble a Cast Iron Radiator for Repair

Full disassembly becomes necessary for extensive rust damage, multiple leaks, or broken sections. If internal sludge severely restricts flow, taking the radiator apart allows thorough cleaning.

Sections with deep cracks or warping often require replacement. Disassembly also helps when restoring antique radiators, as it permits complete stripping and repainting.

Working on a disassembled radiator demands space and time. Ensure proper support for sections to avoid dropping and damaging them. If unsure about reassembly, consult a professional.

Best Epoxy and Sealants for Cast Iron Radiator Repairs

Choosing the right products ensures durability under high heat and pressure. JB Weld HighHeat withstands temperatures up to 2400°F, making it ideal for crack repairs. Devcon Plastic Steel Epoxy bonds strongly to cast iron and resists water exposure.

For sealing threaded fittings, Loctite 592 Copper RTV provides a flexible, heat-resistant barrier. Permatex High-Temp Red RTV works well for gasket sealing and minor leaks.

Always prep surfaces by sanding and degreasing before application. Follow curing times precisely for maximum strength.

How to Restore a Cast Iron Radiator’s Surface

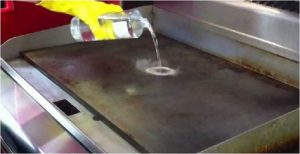

Start by removing old paint and rust with a wire brush, sandblaster, or chemical stripper. Wear protective gear to avoid inhaling dust.

After stripping, apply a rust converter to neutralize remaining corrosion. Primer designed for metal surfaces ensures paint adhesion. Use heat-resistant enamel for the final coat, as standard paint will blister under high temperatures.

For intricate designs, hand-painting may be necessary. Allow each layer to dry fully before applying the next.

Professional vs. DIY Cast Iron Radiator Repair

DIY repairs save money but require skill and patience. Epoxy fixes and gasket replacements are manageable for most homeowners. Disassembly and welding demand specialized tools and expertise.

Professionals handle structural cracks, major leaks, and full restorations efficiently. They also pressure-test systems to ensure no hidden issues remain. Weigh cost against risk—complex repairs often justify hiring an expert.

Replacement Vs. Repair Vs. Restoration

Repair suits minor cracks and leaks. Restoration is best for antique radiators needing cosmetic and functional refurbishment. Replacement becomes necessary if sections are severely damaged or inefficient.

Consider the radiator’s age, condition, and heating efficiency before deciding.

Maintaining Cast Iron Radiators

Annual bleeding removes trapped air. Flushing the system every few years prevents sludge buildup. Inspect for rust and leaks seasonally. Keeping the radiator clean and painted reduces corrosion risks.

Proper care extends lifespan and maintains heating efficiency.

- Read More: Will a Magnet Stick to Cast Iron?